Web Assembly

Davis Aircraft has been designing and manufacturing web assembly for military, commercial and industrial applications for over 60 years. Our stock of web assembly types and sizes represents years of committed research and development. We will work with you to develop special web types for your unique applications.

| Width | PART NO. | Strength | Weight Per Yard | Thickness | Material | Mil. Specifications & Type | |||

|---|---|---|---|---|---|---|---|---|---|

| LBS | Kg | OZ. | Kg | IN. | MM | ||||

| 1.00 inch 25.4 mm |

NW170 | 4000 | 1814 | 1.86 | .052 | 11 | 2.8 | Nylon | MIL-W-4088 TYPE XXV MOD |

| CW180 | 550 | 249 | 1.33 | .037 | .09 | 2.3 | Cotton | MIL-W-530 TYPE III | |

| CW181 | 475 | 215 | .96 | .026 | .07 | 1.8 | Cotton | MIL-W-530 TYPE IIB | |

| NW196 | 2500 | 1134 | 1.15 | .032 | .05 | 1.3 | Nylon | MIL-W-4088 TYPE XVII | |

| NW199 | 6000 | 2722 | 2.05 | .057 | .13 | 3.3 | Nylon | MIL-W-4088 TYPE XVIII | |

| NW200 | 4500 | 2041 | 1.15 | .026 | .08 | 2.0 | Nylon | MIL-W-4088 TYPE XXV MOD | |

| DW222 | 2500 | 1134 | 1.06 | .030 | .07 | 1.8 | Polyester | ||

| NW225 | 600 | 272 | .42 | .012 | .03 | 0.8 | Nylon | MIL-W-4088 TYPE II | |

| NW258 | 4500 | 2041 | 1.5 | .042 | .10 | 2.5 | Nylon | MIL-W-4088 TYPE XXV | |

| CW263 | 1000 | 454 | 1.25 | .035 | .08 | 2.2 | Cotton | MIL-W-5665 TYPE XVII | |

| 1.25 inch 31.8 mm |

CW179 | 590 | 268 | 1.2 | .033 | .06 | 1.5 | Cotton | MIL-W-530 TYPE IIB |

| NW208 | 800 | 363 | .52 | .015 | .03 | .08 | Nylon | MIL-W-4088 TYPE III | |

| NW227 | 3600 | 1633 | 1.70 | .047 | .07 | 1.8 | Nylon | MIL-W-4088 TYPE XXI | |

| 1.50 inch 38.1 mm |

NW183 | 1500 | 680 | .75 | .021 | .04 | 1.0 | Nylon | MIL-W-5038 TYPE IV |

| CW279 | 860 | 390 | 2.40 | .068 | .09 | 2.3 | Cotton | MIL-W-530 TYPE III | |

| NW308 | 8700 | 3035 | 2.8 | .081 | .11 | 2.8 | Nylon | MIL-W-4088 TYPE XXV MOD | |

| 1.75 inch 44.4 mm |

NW159 | 3600 | 1633 | 13.8 | .045 | .05 | 1.3 | Nylon | MIL-W-4088 TYPE VIII |

| NW160 | 8700 | 3946 | 3.70 | .103 | .13 | 3.0 | Nylon | MIL-W-4088 TYPE X | |

| DW167 | 6000 | 2722 | 2.10 | .060 | .07 | 1.8 | Polyester | MIL-W-25361 TYPE II | |

| DW177 | 10000 | 4536 | 3.90 | .109 | .12 | 3.0 | Polyester | MIL-W-25361 TYPE V | |

| NW204 | 15000 | 8804 | 4.90 | .137 | .18 | 4.0 | Nylon | MIL-W-4088 TYPE XXVI | |

| NW211 | 5500 | 2495 | 2.35 | .658 | .08 | 2.0 | Nylon | MIL-W-4088 TYPE VII | |

| NW256 | 10000 | 4536 | 4.10 | .115 | .12 | 3.0 | Nylon | MIL-W-4088 TYPE XIX | |

| NW32 | 9500 | 4309 | 3.50 | .100 | .11 | 2.8 | Nylon | MIL-W-4088 TYPE XXII | |

| DW395 | 10000 | 4536 | 3.90 | .109 | .12 | 3.0 | Polyester | A-A-55242 TYPE V | |

| 2.00 inch 50.8 mm |

NW161 | 5500 | 2495 | 2.45 | .068 | .06 | 1.5 | Nylon | MIL-W-4088 TYPE XXIV |

| NW184 | 2000 | 907 | 1.00 | .028 | .04 | 1.0 | Nylon | MIL-T-5038 TYPE IV MOD | |

| NW280 | 6500 | 2944 | 2.90 | .081 | .06 | 2.0 | Nylon | ||

| NW229 | 4000 | 1814 | 1.65 | .047 | .04 | 1.0 | Nylon | ||

| 3.00 inch 76.2 mm |

CW182 | 1560 | 708 | 4.8 | .134 | .12 | 3.0 | Cotton | MIL-W-530 TYPE III |

| NW231 | 9000 | 4082 | 4.0 | .112 | .08 | 2.0 | Nylon | MIL-W-4088 TYPE IX | |

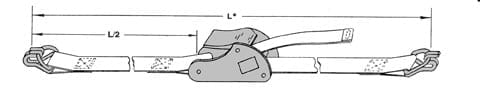

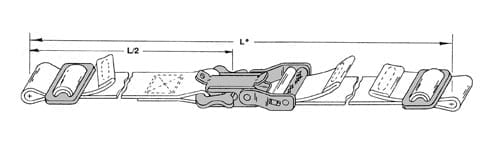

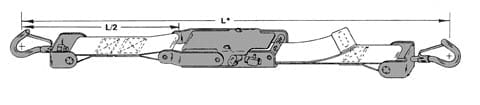

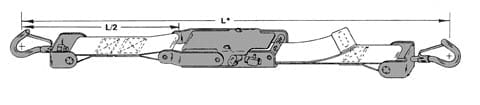

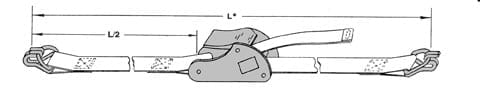

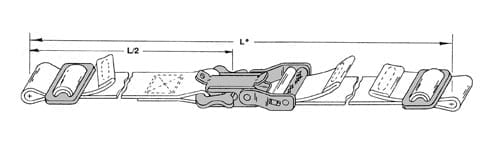

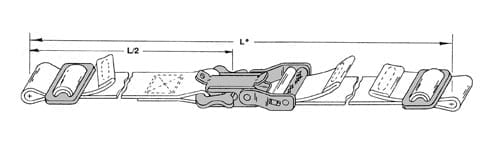

| SERIES NO. Web Assembly |

Buckle | End Hardware | Strength LBS/KG | Webbing PART NO. | Notes |

|---|---|---|---|---|---|

| FDC4513-L | FDC4511F-10 | FDC4511H10 | 1800 / 815 | NW170 | Web color Grey Unless otherwise specified |

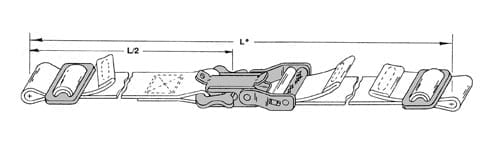

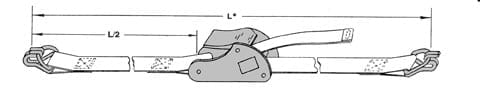

| SERIES NO. Web Assembly |

Buckle | End Hardware | Strength LBS/KG | Webbing PART NO. | Notes |

|---|---|---|---|---|---|

| FDC4513A-L | FDC4511G10 | FDC-4511B-10 | 1800 / 815 | NW170 | Web color Grey Unless otherwise specified |

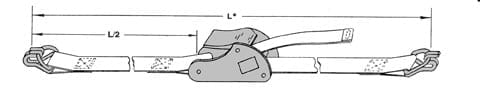

| SERIES NO. Web Assembly |

Buckle | End Hardware | Strength LBS/KG | Webbing PART NO. | Notes |

|---|---|---|---|---|---|

| FDC1575-L | FDC1575-2 | FD2876-1 | 1000 / 453 | NW196 | Web color O.D. Unless otherwise specified |

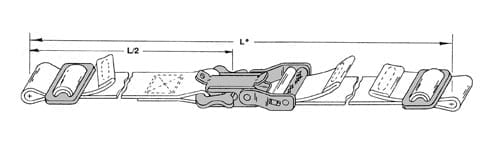

| SERIES NO. Web Assembly |

Buckle | End Hardware | Strength LBS/KG | Webbing PART NO. | Notes |

|---|---|---|---|---|---|

| FDC3605M-L | FDA3606-1 | FD3389M-2 | 2000 / 906 | NW200 | Web color black Unless otherwise specified |

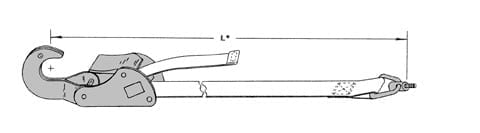

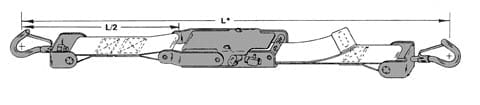

| SERIES NO. Web Assembly |

Buckle | End Hardware | Strength LBS/KG | Webbing PART NO. | Notes |

|---|---|---|---|---|---|

| FDC3700M2-2 | FDA3866M15 | FDA3356M12 | 6000 / 2720 | NW327 | CGU-1/B [MIL-T-27260] NSN1670-00-725-1437 |

| SERIES NO. Web Assembly |

Buckle | End Hardware | Strength LBS/KG | Webbing PART NO. | Notes |

|---|---|---|---|---|---|

| FDC3605A-L | FDA3606 | FDA1125M5 | 2000 / 906 | NW211 | WEB color O.D Unless otherwise specified |

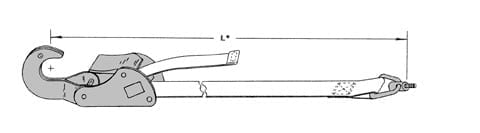

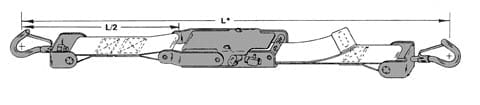

| SERIES NO. Web Assembly |

Buckle | End Hardware | Strength LBS/KG | Webbing PART NO. | Notes |

|---|---|---|---|---|---|

| FDC5770-5 | FDA3866M16 | FDA8104 | 7000 / 3175 | DW395 | Color O.D MIL-T-63960 |

| SERIES NO. Web Assembly |

Buckle | End Hardware | Strength LBS/KG | Webbing PART NO. | Notes |

|---|---|---|---|---|---|

| FDC4513B-L | FDC4511F-20M | FDC4511H20 | 2000 / 906 | NW280 | Web color Grey Unless otherwise specified |

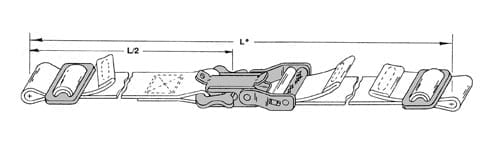

| SERIES NO. Web Assembly |

Buckle | End Hardware | Strength LBS/KG | Webbing PART NO. | Notes |

|---|---|---|---|---|---|

| FDC1575-283 | FDC1720C-6 | SEWN LOOPS | 500 / 226 | NW161 | Web color Red Unless otherwise specified |

| SERIES NO. Web Assembly |

Buckle | End Hardware | Strength LBS/KG | Webbing PART NO. | Notes |

|---|---|---|---|---|---|

| FDC1126 | FDA1123M1 | FDA1125M1 | 1800 / 815 | NW280 | A1A Gear per oMil-T-7181 |

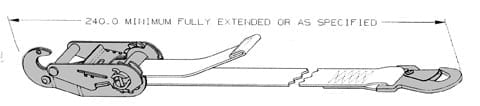

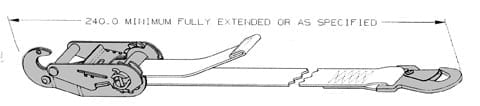

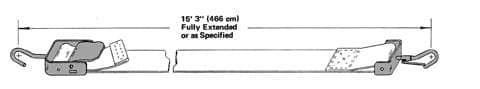

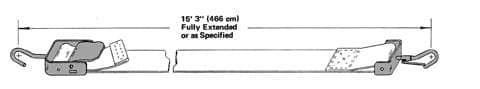

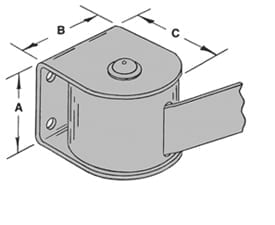

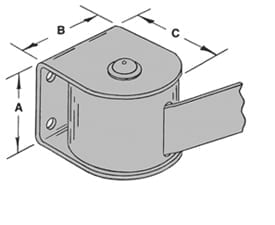

Web Retractors

| PART NO. | Strength LBS/KG | Weight LBS/KG | Capacity IN/MM | A IN/MM | B IN/MM | C IN/MM |

|---|---|---|---|---|---|---|

| FDA7710 Series | 200/91 | .35/80 | 50/1270 | 1.7/43.2 | 2.5/63.5 | 2.7/68.6 |

| FDA7710 Series | 2200+/997+ | .64/29 | 60+/1524+ | 2.0/50.8 | 1.9/48.3 | 2.1/53.3 |

Uses

- Safety Strap – Child, Barrier

- Cargo Retention – Ships, Aircraft (Commercial & Military)

- Coat Closet Restraint – Airlines, Small Passenger Aircraft

- Various Spring Loading Applications – Because of its compact nature as well as being light-weight with adjustable spring tension, it is ideal where weight and size are important

Features

- Corrosion-proof Stainless Steel spring

- Free rotating housing protects Web and allows retraction in any direction

- Available with a wide range of End Fittings & Buckles

- Built for indoor and outdoor use to Aircraft Quality Standards

Features and Benefits:

- Unless otherwise noted, all ratings specified above are the ultimate straight tensile strength

- In tie down configuration, the load capacity is doubled

- Use colors specified by Federal Standard 595 when critical

- Finish specifications

- All finishes meet the highest aircraft quality standards

- Aluminum: Anodized per MIL-A-8625 Type I

- Steel: Cadmium-plated per QQ-P-416Type I or Type II or Chrome Plated

- Stainless Steel: Passivate per QQ-P-35