Cargo Restraint Hardware

Cargo restraint systems require a vast amount of components and hardware in order to ensure proper operation. When searching for the proper materials, it is vital to review all of the information available for your specific application.

Please examine the following cargo restraint hardware offerings:

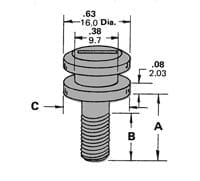

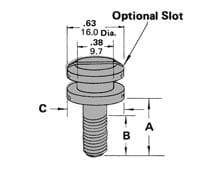

Studs

The following stud inventory offers a wide variety of designed uses, but all are equipped with strong, durable Davis-made engineering and materials. Please note the following details about our stud hardware, which apply only to specific models. Please check our entire inventory for part numbers and specifications.

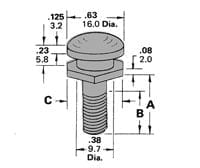

| PART NO. | Strength LBS/KG. | Weight LBS/KG | Material | A IN./MM. | B IN./MM. | C IN./MM. | THREAD TYPE |

|---|---|---|---|---|---|---|---|

| FD4015 | .029/.013 | .63/.16 | .57/14 | .25-28/UNF-2A | |||

| FD4015-3 | 4000/1814 | .034/.015 | 4130/Steel | .88/22 | .82/21 | .63/16 | .25-20/NC-2A |

| FD4015-4 | 4000/1814 | .029 | 4130/Steel | .38/10 | .32/8 | .63/16 | .25-28/UNF-2A |

| FD4015-5 | .045/.203 | 1.78/45 | .47/12 | .25-28/UNF-3A |

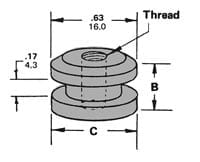

| PART NO. | Strength LBS/KG. | Weight LBS/KG | Material | A IN./MM. | B IN./MM. | C IN./MM. | THREAD TYPE |

|---|---|---|---|---|---|---|---|

| FD4015M4-1 | .038/.017 | .44/11 | .38/10 | .63/16 | .38-24/UNF-3A | ||

| FD4015M4-2 | 4000/1814 | .031/.014 | 4140/Steel | .62/16 | .46/12 | .56/14 | .25-28/UNF-3A |

| FD4015M4-4 | 1814/12 | .046/.021 | .70/18 | .46/12 | .63/16 | .38-24/UNF-3A |

| PART NO. | Strength LBS/KG. | Weight LBS/KG | Material | A IN./MM. | B IN./MM. | C IN./MM. | THREAD TYPE |

|---|---|---|---|---|---|---|---|

| FD4015M8 | 4000/1814 | .032/.015 | 4130/Steel | .69/18 | .63/16 | .63/16 | .38-24/UNF-3A |

| FD4015M11 | 2500/1134 | .028/.013 | 17-4/CRES | .59/15 | .36/9 | .62/16 | .M5X0.8/5 mm |

| PART NO. | Strength LBS/KG. | Weight LBS/KG | Material | A IN./MM. | B IN./MM. | C IN./MM. | THREAD TYPE |

|---|---|---|---|---|---|---|---|

| FD2493 | 4000/1814 | 016/.007 | 4130/Steel | 38/06 | .63/16 | .25-28/UNF-2B | |

| FD2493M2-2 | 4000/1814 | .015/.006 | 4130/Steel | .44/11 | .63/16 | .28-28/UNF-2B |

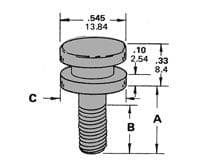

| PART NO. | Strength LBS/KG. | Weight LBS/KG | Material | A IN./MM. | B IN./MM. | C IN./MM. | THREAD TYPE |

|---|---|---|---|---|---|---|---|

| FD1223 | .030/.014 | .63/16.0 | .57/14.5 | .25-20/UNC-2A | |||

| FD1223-1 | 4000/1814 | .032/.015 | 4130/Steel | .77/19.5 | .71/18.0 | .55/.14 | .25-20/UNC-2A |

| FD1223-2 | 4000/1814 | .030/.014 | 4130/Steel | .63/16.0 | .57/14.5 | .55/14 | |

| FD1223-4 | .028/.035 | .34/8.6 | .28/7.14 | .25-28/UNF-2A |

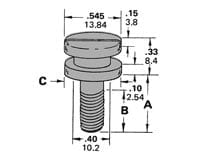

| PART NO. | Strength LBS/KG. | Weight LBS/KG | Material | A IN./MM. | B IN./MM. | C IN./MM. | THREAD TYPE |

|---|---|---|---|---|---|---|---|

| FD1223M2 | 4000/1814 | .030/.014 | 4130/Steel | .63/16.0 | .57/15 | .55/14 | .25-28/UNF-3A |

| FD1223M2-1 | 4000/1814 | .028/.013 | 4130/Steel | 1.13/29 | 1.071/27 | .55/14 | .25-28/UNF-3A |

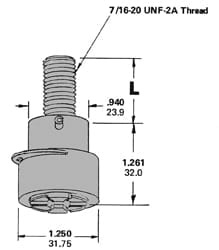

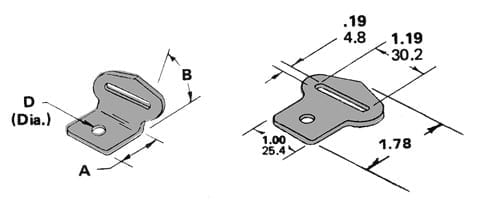

| PART NO. | D IN./MM. | MS PART NO. | L IN./MM. |

|---|---|---|---|

| FDC2650M-1 | .853/21.6 | MS22034-1 | 2.156/54.7 |

| FDC2650M-2 | .883/22.4 | MS22034-2 | 2.156/54.7 |

| FDC2650M-3 | .866/22.0 | MS22034-3 | 2.156/54.7 |

| FDC2650M-4 | .750/1931 | MS22034-4 | 2.325/59.1 |

| FDC2650M-5 | .892/22.7 | MS22034-5 | 2.325/59.1 |

| FDC2650M-6 | .916/23.3 | MS22034-6 | 2.325/59.1 |

- FDC2650M5-*SERIES

- Sample Callout: FDC2650M5-5 denotes “L” Dimension of 5/16 inch

- *=Number designating length “L” in increments of 1/16 inches

Benefits and Features (includes specific benefits of certain models only):

- Accommodate FDC2650M Series Chair Stud Fittings and Stud Pickup Buckles

- Functional equivalence to AN7516 Plate Stud

- Screwdriver slot in head

- Hex shoulder for securing

- Slot-threaded ends included

- Customized Studs to meet your unique applications

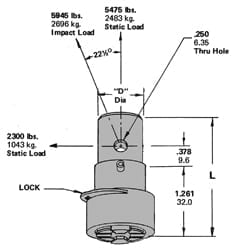

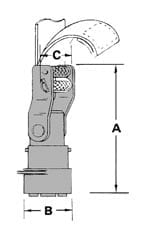

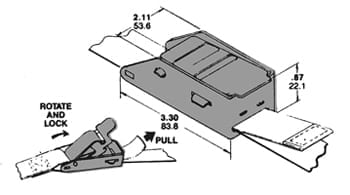

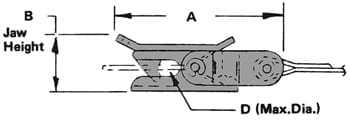

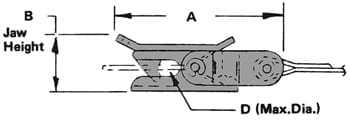

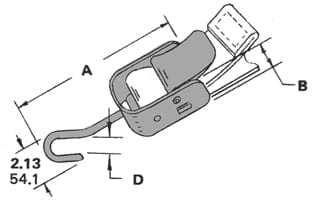

Studs Pickup

Stud pickup buckles are used exclusively for cargo tie downs and are typically used with floor plates.

Benefits and Features:

- Attachable to studs per AN7516, FD2493 and FD4015

- 360 degree rotation around stud

- 90 degree swivel in any direction out of vertical

- 100% strength maintained at 22 1/2″ out of vertical

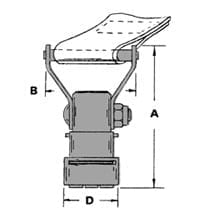

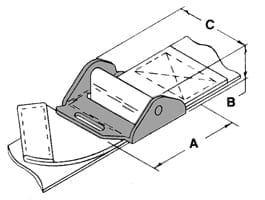

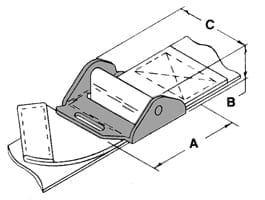

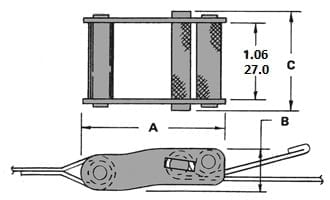

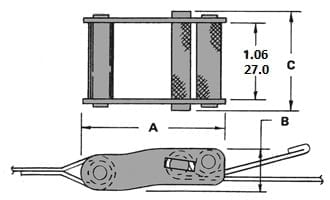

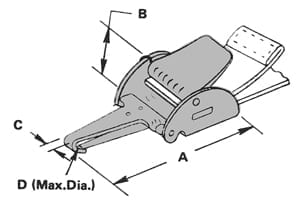

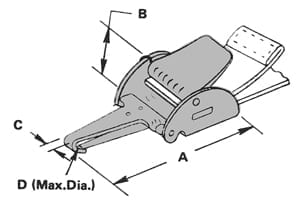

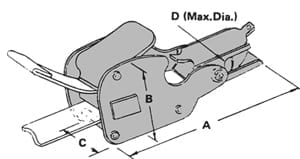

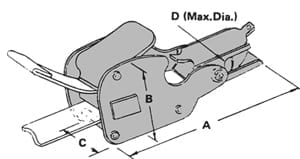

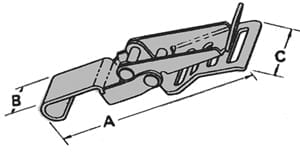

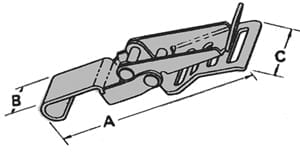

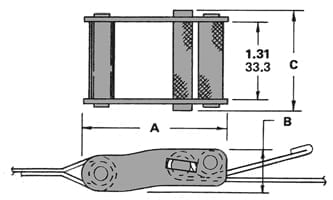

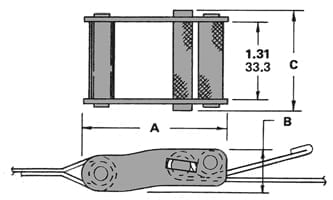

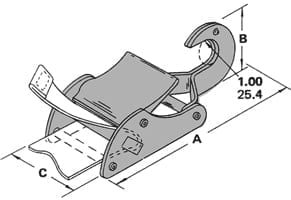

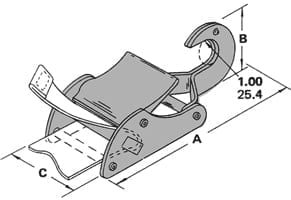

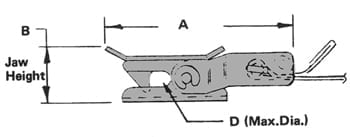

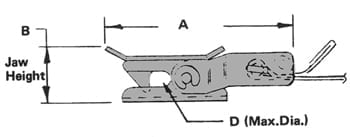

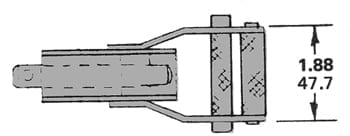

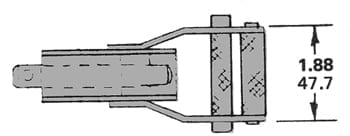

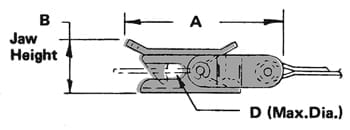

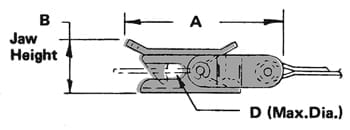

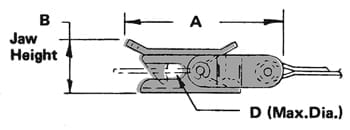

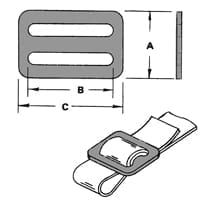

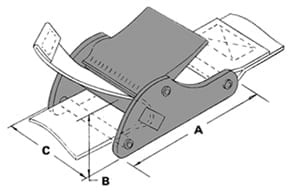

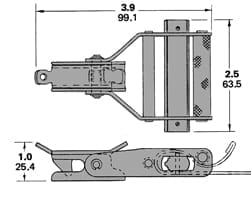

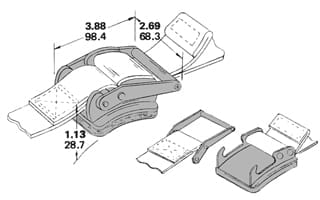

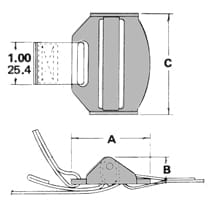

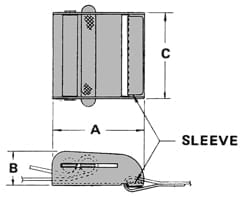

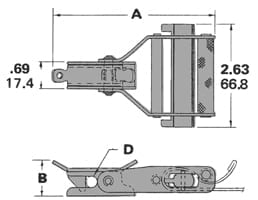

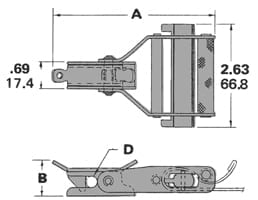

Stud Pickups: FDC1920 Series

| PART NO. | Strength LBS/KG. | Weight LBS/KG | Material | A IN./MM. | B IN./MM. | C IN./MM. |

|---|---|---|---|---|---|---|

| FDC1920M1-2 | 2600/1180 | .012/.054 | 4130/Steel | 2.42/61.5 | .80/20.3 | .80/20.3 |

| FDC1920-2 | 1700/771 | .013/.059 | 4130/Steel | 2.75/69.8 | .80/20.3 | .80/20.3 |

- Cam type adjustment

- Releasable under load

- Web- NW196, NW200 for FDC3120 and FDC3120M4

- Web- NW170 for FDC3120M3

- FDC1920M1-2 (non-adjustable as shown)

- FDC1920-2 (with friction lock web adjustment)

- Web- NW170, NW200, NW196

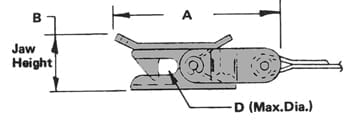

| PART NO. | Strength LBS/KG. | Weight LBS/KG | Material | A IN./MM. | B IN./MM. | C IN./MM. |

|---|---|---|---|---|---|---|

| FDC1920M1-3 | 2700/1224 | .013/.06 | 4130/Steel | 2.41/61.2 | .80/20.3 | .80/20.3 |

| FDC1920-3 | 2700/1224 | .25/.11 | 4130/Steel | 2.75/70.0 | .80/20.3 | .80/20.3 |

- FDC1920M1-3 (non-adjustable)

- FDC1920-3 (with Friction Lock Web adjustment as shown)

- Web- any type 1.25 (32mm) wide, rating based on NW227

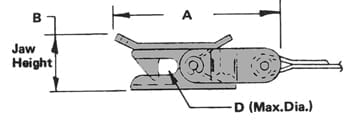

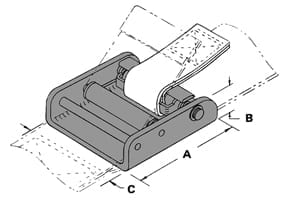

| PART NO. | Strength LBS/KG. | Weight LBS/KG | Material | A IN./MM. | B IN./MM. | C IN./MM. |

|---|---|---|---|---|---|---|

| FDC3120 | 1400/634 | .20/.090 | Alum/Steel | 3.5/88.9 | 1.70/43.1 | 1.44/36.5 |

| FDC3120M3 | 1500/679 | .30/.130 | Alum/Steel | 3.75/95.2 | 1.75/44.4 | 1.50/38.1 |

| FDC3120M4 | 700/317 | .16/.073 | Alum/Steel | 2.50/63.5 | .94/23.8 | 1.42/36 |

- Cam Type Adjustment

- Releasable under load

- Web – NW196, NW200, for FDC3120, FDC3120M4

- Web – NW170 for FDC3120M3

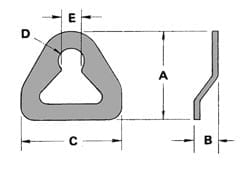

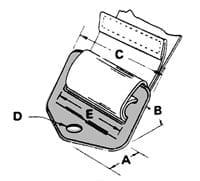

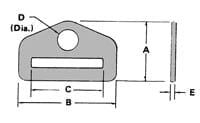

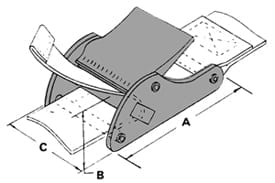

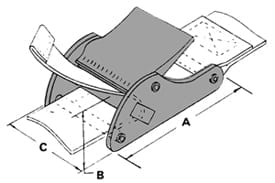

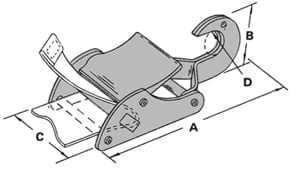

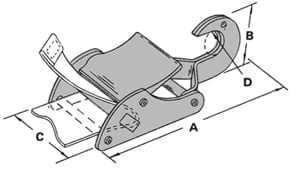

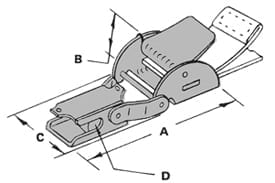

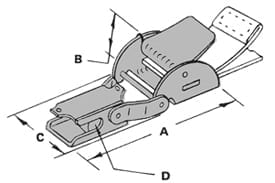

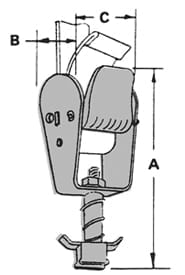

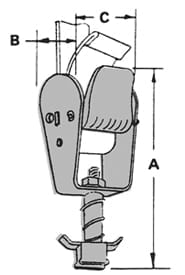

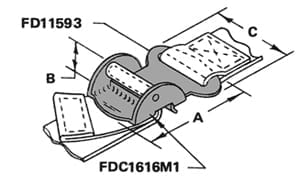

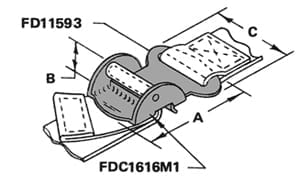

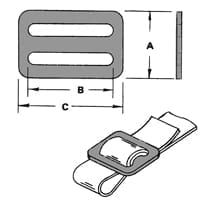

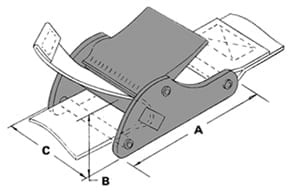

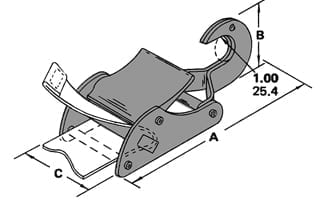

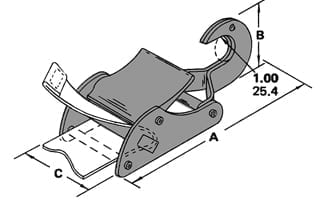

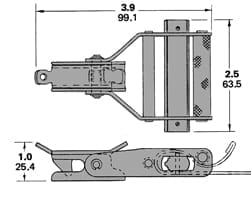

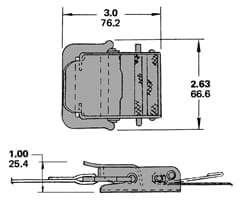

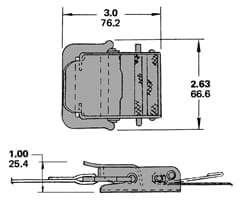

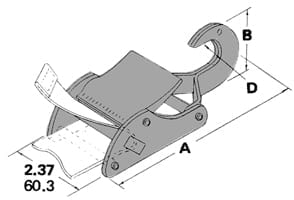

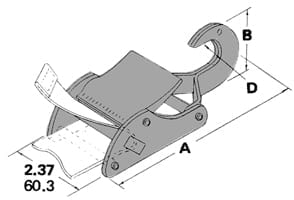

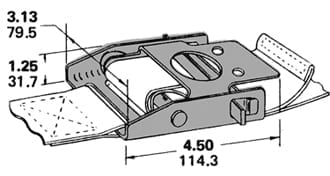

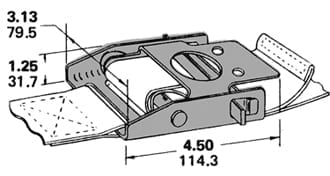

Chair Stud Type: FDC2650 Series

| PART NO. | Strength LBS/KG. | Weight LBS/KG | Material | A IN./MM. | B IN./MM. | C IN./MM. |

|---|---|---|---|---|---|---|

| FDC2650M3 | 2000/906 | .036/.163 | Alum/Steel | 3.43/87.1 | 1.25/31.7 | 1.43/36.3 |

| FDC2650M1-10 | 2000/906 | .030/.136 | Alum/Steel | 3.06/77.7 | 1.25/31.7 | 1.30/33.0 |

- FDC2650M3 (adjustable)

- FDC2650M1-10 (non-adjustable)

- Web- NW170, NW196 and NW200

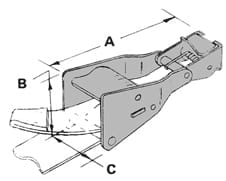

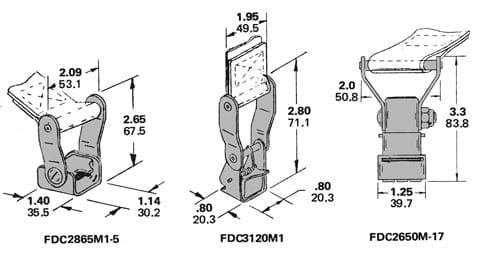

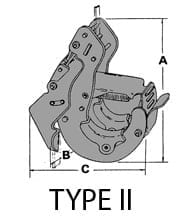

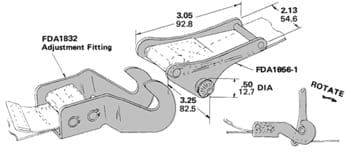

Stud Pickups for 1 3/4″ Web

| PART NO. | Strength LBS/KG. | Weight LBS/KG | Material | Notes |

|---|---|---|---|---|

| FDC2865M1-5 | 7000/3175 | .38/.17 | 4130/Steel | For Pop-up or non-recessed studs |

| FDC3120M1 | 1200/544 | .14/.06 | Steel /Alum | Order FDC3120M1-2 for Type II Cad Parts |

| FDC2865M1-17 | 2000/907 | .27/.12 | Alumn / Steel | FDC2650 Series Chair Stud w/ attachment |

- Fits AN7516 and our FD4015 Series Studs

- 360 degree rotation around stud

- Swivel 90 degree our of vertical

- Use with any type 1 3/4″ Web

- FDC2650M1-10 (non-adjustable)

- Web- NW170, NW196 and NW200

Stud Pickups for 2″ Web

| PART NO. | Strength LBS/KG. | Weight LBS/KG | Material | A IN./MM. | B IN./MM. | C IN./MM. |

|---|---|---|---|---|---|---|

| FDC2650M1-20 | 2000/907 | .27/.12 | Steel/Alum | 3.31/84.0 | 2.20/55.9 | 1.25/31.7 |

End Fittings

End fittings listed below are just a sample of what we have available in stock. In order to accommodate the variety of applications calling for end fittings, we feature a variations including: fittings with studs, various holes and multiple bend angles.

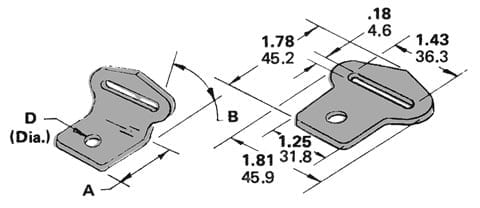

End Fittings: 1″ Web

| PART NO. | Strength LBS/KG. | Weight LBS/KG | Material | Finish | A IN./MM. | B IN./MM. | D IN./MM. |

|---|---|---|---|---|---|---|---|

| FD1268-2 | 500/227 | Type I/C1-2 | |||||

| FD1268-2-2 | 500/227 | .03/.14 | Carbon/Steel | Type II/C1.2 | 26/6.6 | ||

| FD1268-2-3 | 500/227 | .03/014 | Carbon/Steel | Type II | .88/22.3 | 30° | |

| FD1268-2-4 | 500/227 | Type II/C1.1 | .33/8.4 | ||||

| FD1268M3 | 1000/454 | .05/.02 | 4130/Steel | Type II/C1.2 | .44/11.2 | ||

| FD1268M4 | 1000/454 | .05/.02 | 4130/Steel | Type II/C1.2 | 1.00/25.4 | 15° | .39/9.9 |

| FD1281 | 500/227 | Type I/C1.2 | |||||

| FD1281-2 | 500/227 | Low/Carbon | .26/6.6 | ||||

| FD1281-3 | 500/227 | Carbon/Steel | Type II/C1.2 | ||||

| FD1281-4 | 500/227 | .44/11.2 | |||||

| FD1281C | 1400/635 | .03/.014 | 302 or/304 | Ball/Burnish | 90° | .26/6.6 | |

| FD1281C-2 | 1400/635 | Stainless/Steel | Ball/Burnish | .81/20.5 | .44/11.2 | ||

| FD1281-2M1 | 650/295 | .29/7.4 | |||||

| FD1281M5 | 650/295 | Low/Carbon | Type I/C1.2 | .33/8.3 | |||

| FD1281M6 | 650/295 | Carbon/Steel | Type I/C1.2 | ||||

| FD1281M8 | 1700/771 | .05/.02 | 60° | .26/6.6 | |||

| FD1281M9 | 3000/1361 | .05/.02 | 4130/Steel | Type II/C1.2 | 90° | .26/6.6 | |

| FD3389-2 | 500/227 | .03/.014 | 1020/Steel | ||||

| FD3389-5 | 2500/1134 | Type I/C1.2 | 0° | .33/8.3 | |||

| FD3389M | 2500/1134 | .05/.02 | 4130/Steel | Type I/C1.2 | .26/6.6 | ||

| FD3389M-2 | 2500/1134 | .81/20.5 | 15° | .26/6.6 |

| PART NO. | Strength LBS/Kg | Weight LBS/Kg | Material | Finish* | A IN./MM | B IN./MM | D IN./MM |

|---|---|---|---|---|---|---|---|

| FD1268 | 1020/Steel | .87/22.1 | 30° | .257/6.5 | |||

| FD1268M1 | 500/227 | .04/.018 | 1020/Steel or Equivalent | Type I/C1.2 | .87/22.1 | 30° | .406/10.3 |

| FD3389-3 | . | 1020/Steel or Equivalent | – | 0° | .502/12.7 |

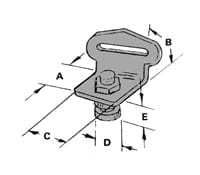

| PART NO. | Strength LBS/Kg | Weight LBS/Kg | Material | A IN./MM | B IN./MM | C IN./MM | D IN./MM | E IN./MM |

|---|---|---|---|---|---|---|---|---|

| FD7389-1 | 3000/1361 | .06/.027 | 4130/Steel | 1.77/45 | 49° | 1.62/41.1 | .39/9.9 | .88/22.3 |

| FD7389-2 | 3000/1361 | .06/.027 | 4130/Steel | 45/2.03 | – | 1.62/41.1 | .39/9.9 | .88/22.3 |

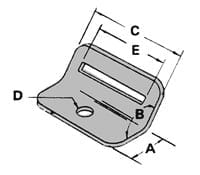

| PART NO. | Strength LBS/Kg | Weight LBS/Kg | Material | A IN./MM | B IN./MM | C IN./MM | D IN./MM | E IN./MM |

|---|---|---|---|---|---|---|---|---|

| FDA1261-2 | Plate/1020 | .87/22.1 | 30° | |||||

| FDA1282 | 1100/.499 | 056/.03 | Steel/Stud | .81/20.5 | 90° | 1.00/25.4 | 5.45/13.8 | .33/8.4 |

| FDA1282M1-1 | 4130/Steel | .81/20.5 | 60° |

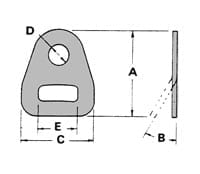

| PART NO. | Strength LBS/Kg | Weight LBS/Kg | Material | A IN./MM | B IN./MM | C IN./MM | D IN./MM | E IN./MM |

|---|---|---|---|---|---|---|---|---|

| FD7281 | 3000/1361 | .045/.020 | 4130/Steel | 1.57/39.9 | .42/10.6 | 1.68/42.7 | .406/10.3 | .36/9.1 |

| FD7281-2 | 900/408 | .014/.006 | 2024/Alum | 1.57/39.9 | .42/10.6 | 1.68/42.7 | .406/10.3 | .36/9.1 |

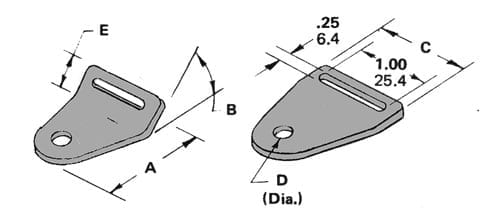

End Fittings: 1 1/4″ Web

| PART NO. | Strength LBS/KG. | Weight LBS/KG | Material | A IN./MM. | B IN./MM. | C IN./MM. | D IN./MM. | E IN./MM. |

|---|---|---|---|---|---|---|---|---|

| FDA1261 | 500/227 | .08/.036 | 1020/Steel | .87/22.1 | 30° | 1.25/31.7 | .545/13.8 | .33/8.3 |

| PART NO. | Strength LBS/KG. | Weight LBS/KG | Material | A IN./MM. | B IN./MM. | C IN./MM. | D IN./MM. | E IN./MM. |

|---|---|---|---|---|---|---|---|---|

| FD2430 | 1.00/25.4 | 116° | ||||||

| FD2430-7 | 2500/1134 | .18/.08 | Steel/1010-1020 | 1.00/25.4 | 90° | 2.75 | .406 | 2.00 |

| FD2430M2-3 | 2500/1134 | .18/.08 | Steel/1010-1020 | 1.00/25.4 | 145° | 69.8 | 10.3 | 50.8 |

| FD2430M7 | 1.00/25.4 | 90° |

| PART NO. | Strength LBS/KG. | Weight LBS/KG | Material | A IN./MM. | B IN./MM. | C IN./MM. | D IN./MM. | E IN./MM. |

|---|---|---|---|---|---|---|---|---|

| FD7389 | 3100/1406 | 1.71/43.4 | 49° | 1.62/41.1 | .386/9.8 | 1.00/25.4 | ||

| FD7389-2 | 3100/1406 | 2.04/51.8 | 0° | 1.62/41.1 | .386/9.8 | 1.00/25.4 | ||

| FD7295-1 | .512/13 | |||||||

| FD7295-3 | .06/.027 | 4130/Steel | .390/9.9 | |||||

| FD7295-5 | 3200/1451 | 21.0/53.3 | 0° | 1.75/44.4 | .327/8.3 | .96/24.4 | ||

| FD7295-7 | 257/6.5 | |||||||

| FD7295-19 | .718/18.2 |

| PART NO. | Strength LBS/KG. | Weight LBS/KG | Material | A IN./MM. | B IN./MM. | C IN./MM. | D IN./MM. | E IN./MM. |

|---|---|---|---|---|---|---|---|---|

| FD1543-2 | 3200/1451 | .20/.09 | 4130/Steel | .87/22.2 | 38° | 2.75/69.8 | .450/11.4 | 2.00/50.8 |

End Fittings: 1 3/4″ Web

| PART NO. | Strength LBS/KG. | Weight LBS/KG | Material | A IN./MM. | B IN./MM. | C IN./MM. | D IN./MM. | E IN./MM. |

|---|---|---|---|---|---|---|---|---|

| FD1457 | 2400/1088 | .078/.035 | 4130/Steel | 2.68/68.1 | 2.62/66.5 | 1.88/47.8 | .281/7.13 | .093/2.4 |

| FD1457M1 | 3000/1361 | .11/.049 | 4130/Steel | 2.68/68.1 | 2.62/66.5 | 1.88/47.8 | .316/8.02 | .125/3.17 |

End Fittings: 2″ Web

| PART NO. | Strength LBS/Kg | Weight LBS/Kg | Material | A IN./MM | B IN./MM | C IN./MM | D IN./MM | E IN./MM |

|---|---|---|---|---|---|---|---|---|

| FD1497M | 3000/1361 | .281/7.1 | ||||||

| FD1497M3 | 3000/1361 | .075/.034 | 4130/Steel | .344/8.7 | .100/2.54 | |||

| FD1497M8 | 3000/1361 | .250/6.3 | ||||||

| FD1497M12 | 1700/771 | .046/.02 | 2024/Alum | 2.69/68.3 | 2.87/72.9 | 2.19/55.5 | .281/7.1 | .160/4.06 |

| FD1497M15 | 3000/1361 | .075/.034 | 4130/Steel | .500/12.7 | .100/25.4 | |||

| FD1497M16 | 1700/771 | .046/.02 | 2024/Alum | .375/9.5 | .160/4.06 | |||

| FD1497M18 | 3000/1361 | .075/.034 | 4130/Steel | .390/9.9 | .100/2.54 |

| PART NO. | Strength LBS/Kg | Weight LBS/Kg | Material | A IN./MM | B IN./MM | C IN./MM | D IN./MM | E IN./MM |

|---|---|---|---|---|---|---|---|---|

| FD3490 | 3600/1632 | .11/049 | 4130/Steel | 1.69/42.9 | 2.75/69.8 | 2.00/50.8 | .531/13.5 | .125/3.17 |

| FD3490-2 | 3000/1359 | .08/.04 | 4130/Steel | 1.69/42.9 | 2.75/69.8 | 2.00/50.8 | .406/10.3 | .095/2.41 |

| FD3490-4 | 3000/1359 | .08/.04 | .325/8.3 | .095/2.41 |

Features and Benefits:

- Cadmium plating available for superior strength

- Snap-on plating offered for greater usability

- Adjustable variation available

- Ultra lightweight for maximum performance capability

- Customized End Fittings to meet your unique applications

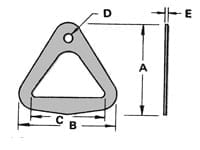

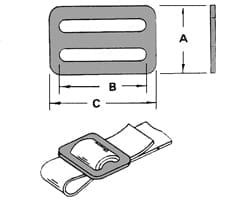

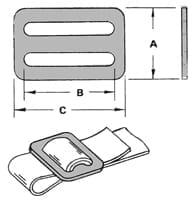

Buckles: 1″ Web

Friction type and the spring-loaded Cam Type buckles/adjusters represent our finest offerings for 1″ web buckles/adjusters. Most of our adjusters may be equipped with release hooks or without a keeper for applications that require separation. The buckles/fasteners listed below represent a sample of our current inventory; please contact us if you would like more information.

| PART NO. | Strength LBS/Kg | Weight LBS/Kg | Material | A IN./MM | B IN./MM | C IN./MM |

|---|---|---|---|---|---|---|

| FD1932-1 | 2100/951 | .050/.022 | 4130/Steel | 1.44/36.5 | 1.25/31.7 | 1.68/42.7 |

| FD2876-1 | 1300/589 | .050/.022 | 4130/Steel | 1.25/31.7 | 1.06/26.9 | 1.50/36.1 |

| FD1932-2 | 700/318 | .018/.010 | 2020/Alum | 1.44/36.5 | 1.25/31.7 | 1.68/42.7 |

| FD2876-2 | 1100/499 | .018/.010 | 2024/Alum | 1.25/31.7 | 1.06/26.9 | 1.50/38.1 |

Bar Slide

- FD1932 Series for use with Webs NW170 and NW200

- FD2876 Series for use with Web NW196

| PART NO. | Strength LBS/Kg | Weight LBS/Kg | Material | A IN./MM | B IN./MM | C IN./MM |

|---|---|---|---|---|---|---|

| FDA7455-3 | 1450/657 | .04/.02 | Stainless/Alum | 1.6/40.6 | .45/11.4 | 1.2/30.5 |

Pull Tab Release

- Friction lock adjustment

- Specify length and color of pull tab if required

- Web-NW196

| PART NO. | Strength LBS/Kg | Weight LBS/Kg | Material | A IN./MM | B IN./MM | C IN./MM |

|---|---|---|---|---|---|---|

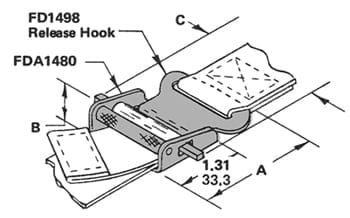

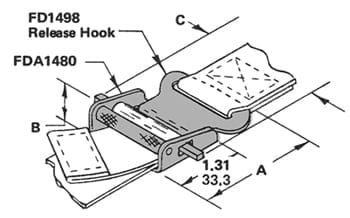

| FDA1480-2M | 1000/453 | .11/.049 | 4130/Steel | 1.25/31.8 | .62/15.7 | 1.69/42.9 |

All Steel

- Available with FD1159-2 Release Hook

- Web-NW196

- High strength

| PART NO. | Strength LBS/Kg | Weight LBS/Kg | Material | A IN./MM | B IN./MM | C IN./MM |

|---|---|---|---|---|---|---|

| FDA1578AA | 800/363 | .04/.02 | 2024/Alum | 2.00/50.8 | .60/15.0 | 1.38/35.1 |

| FDA1578M2 | 2100/952 | .011/.05 | 4130/Steel | 2.00/50.8 | .60/15.0 | 1.38/35.1 |

| FDA1578M7 | 2500/1130 | .06/.03 | Gal 4V/Ti | 2.00/50.8 | .60/15.0 | 1.38/35.1 |

High Strength

- Web-NW196 or NW200

- Friction Locking

| PART NO. | Strength LBS/Kg | Weight LBS/Kg | Material | A IN./MM | B IN./MM | C IN./MM |

|---|---|---|---|---|---|---|

| FDC4511F-10 | 1800/816 | .22/.100 | Steel/Alum | 3.0/76.2 | 1.47/37.3 | 1.37/34.9 |

NAS1211F10

- Available with FD1682-2 Release Hook

- Web-NW170

| PART NO. | Strength LBS/Kg | Weight LBS/Kg | Material | A IN./MM | B IN./MM | C IN./MM |

|---|---|---|---|---|---|---|

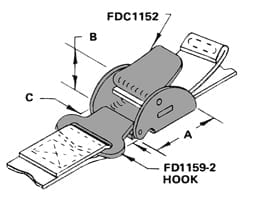

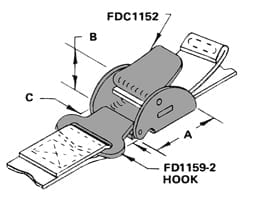

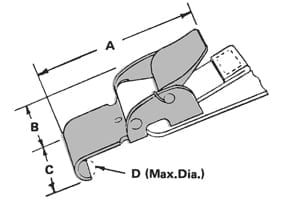

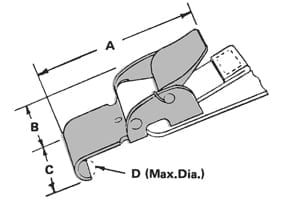

| FDK1152 | 700/317 | .11/.049 | 2024/Alum | 1.66/42.2 | .94/23.9 | 1.42/36.1 |

Cam Type

- Includes FD1159-2 Hook

- FDC1152 buckle without release hook (700 lbs.)

- FDC1152 buckle may be used with FDA1682-2 Keepered hook

- Web-NW200 or NW196 (500 lbs.)

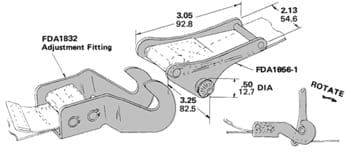

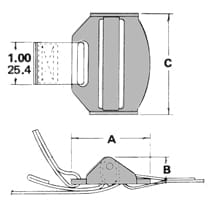

Adjusters/Pickup Type: 1″ Web

These Cam Type Adjusters were principally developed as ring pickups for cargo floors and wall mounts. All of them release easily under load. Strengths range between 350 lbs. (159 kg.) and 1800 lbs. (816 kg.) straight tension. Remember, when assembly is used in loop, as with most tie down applications, strength is virtually doubled that of straight tension.

| PART NO. | Strength LBS/Kg | Weight LBS/Kg | Material | A IN./MM | B IN./MM | C IN./MM | D IN./MM |

|---|---|---|---|---|---|---|---|

| FDA5352 | 700/317 | .18/081 | Zinc Cam/Alum | 3.25/82.5 | 1.50/38.1 | 1.0/25.4 | .32/8.1 |

Fixed Hook Adjuster

- Web – NW200, NW196 (500 lbs. [227 kg.])

| PART NO. | Strength LBS/Kg | Weight LBS/Kg | Material | A IN./MM | B IN./MM | C IN./MM | D IN./MM |

|---|---|---|---|---|---|---|---|

| FDA4385M1 | 700/317 | .28/.13 | Alum/Steel | 5.25/133.3 | 1.5/38.1 | .25/6.3 | .81/20.5 |

| FDC1152H | 350/136 | .16/.074 | Alum/Steel | 3.50/88.95 | .94/23.8 | .20/5.1 | .32/8.1 |

Adjuster with Keeper

- Web – NW200, NW196 (500 lbs. [227 kg.])

- FDA4385M1 includes Swivel Hook feature

| PART NO. | Strength LBS/Kg | Weight LBS/Kg | Material | A IN./MM | B IN./MM | C IN./MM | D IN./MM |

|---|---|---|---|---|---|---|---|

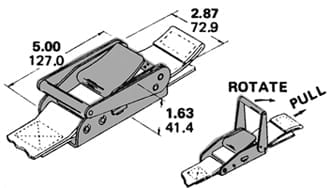

| FDC4511G-10 | 1800/815 | .39/.177 | Alum/Steel | 5.00/127.0 | 1.70/43.2 | 1.37/34.9 | 1.00/25.4 |

Adjuster with Hook

- Per NAS1211G10 except for overall length

- Web – NW170

| PART NO. | Strength LBS/Kg | Weight LBS/Kg | Material | A IN./MM | B IN./MM | C IN./MM | D IN./MM |

|---|---|---|---|---|---|---|---|

| FDC3140M3 | 1300/589 | .32/.145 | Alum/Steel | 4.00/101.6 | 1.75/44.4 | 1.50/38.1 | .25/6.3 |

Heavy Duty Ring Pickup

- Minimum Ring inside diameter 1″ [25 mm]

- Web – NW170

| PART NO. | Strength LBS/Kg | Weight LBS/Kg | Material | A IN./MM | B IN./MM | C IN./MM | D IN./MM |

|---|---|---|---|---|---|---|---|

| FDC1575M7 | 700/317 | .25/.113 | Alum/Steel | 4.00/101.6 | .94/23.9 | 1.60/40.6 | .25/6.4 |

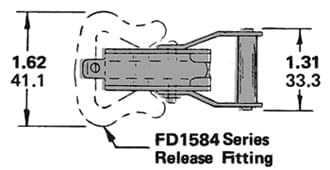

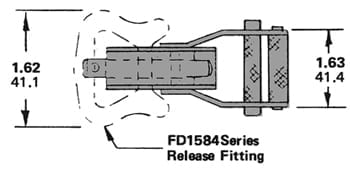

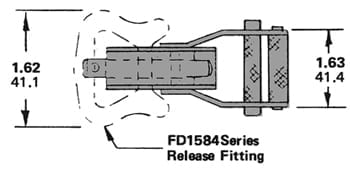

Ring Pickup Adjuster

- Minimum Ring inside diameter 1.0″ [25 mm]

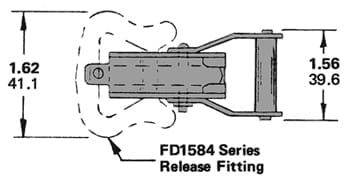

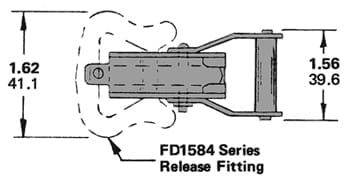

- Can be used with See Ring per FDC3540 or Release Fitting FD1584

- Web – NW200, (NW196 500 lbs. [228 kg.])

| PART NO. | Strength LBS/Kg | Weight LBS/Kg | Material | A IN./MM | B IN./MM | C IN./MM |

|---|---|---|---|---|---|---|

| FDA8959 | 750/340 | .20/.09 | Steel | 4.62/117 | .89/22.6 | 1.45/36.8 |

Over Center Hook

- Adjustable

- Hook diameter .38″ [9.6 mm]

- Pre-load 200 lbs. [90.7 kg.]

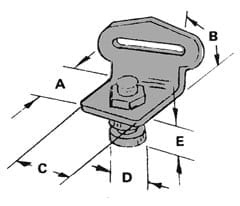

| PART NO. | Strength LBS/Kg | Weight LBS/Kg | Material | A IN./MM | B IN./MM | C IN./MM |

|---|---|---|---|---|---|---|

| FDC4385-3 | 3000/1362 | .13/.058 | 4130/Steel | 2.5/63.5 | 1.62/41.1 | 1.25/31.75 |

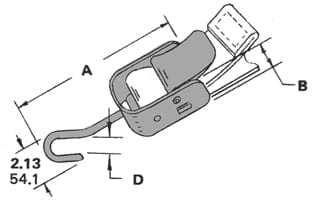

| FDC4385 | 1300/589 | .24/.108 | Alum/Steel | 3.5/88.9 | 1.5/38.1 | 1.6/40.6 |

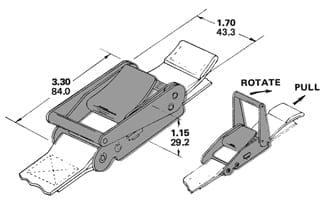

Track Pickup

- MS33601 Attachment

- FDC4385 Adjustable as shown

- FDC4385-3 Non-adjustable

- Web – NW170

- This buckle is made to fit all standard seat tracks per MS33601

- Web is releasable under load by Lift Tab

- Lift clip and slide to disengage

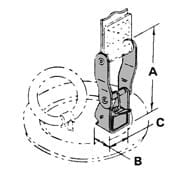

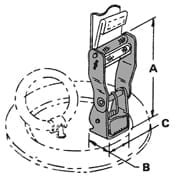

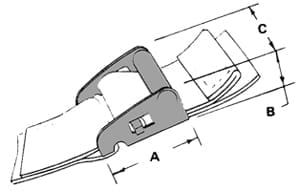

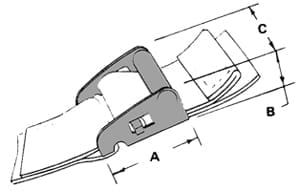

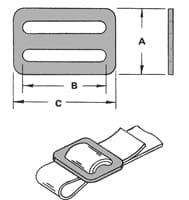

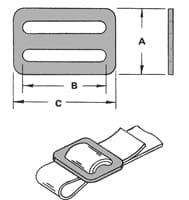

Ty-Clips: 1″ Web

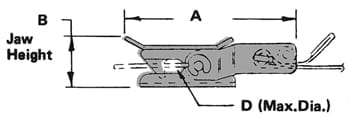

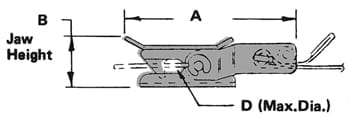

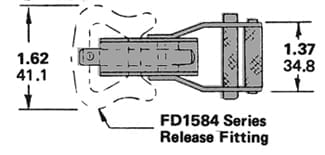

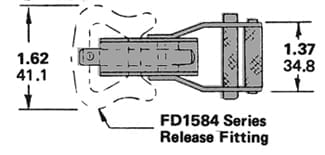

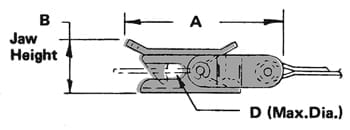

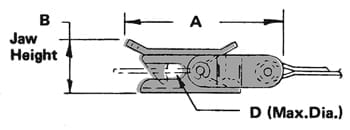

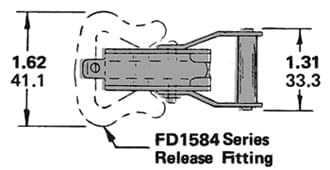

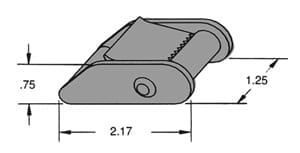

Ty-clips are our most extensively used buckles for cargo nets and general purpose tie downs. They are attachable to FD1584 series release fittings which include pins or rings.

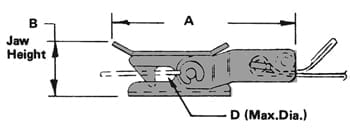

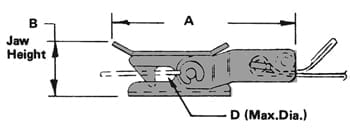

| PART NO. | Strength LBS/Kg | Weight LBS/Kg | Material | A IN./MM | B IN./MM | D IN./MM | Notes |

|---|---|---|---|---|---|---|---|

| FDC1575M1 | 2000/908 | .17/.077 | 4130/Steel | 3.0/76.2 | .87/22 | .25/6.35 | |

| FDC1575-2 | 1000/453 | .19/.086 | 4130/Steel | 3.0/76 | .87/22 | .19/5 | Includes FD1584 |

| FDC1575AA-2 | 800/362 | .06/.040 | Alum/Steel | 3.0/76 | .87/22 | .25/6 | Steel Cover Alum Frame |

| FDC1575B0 | 1600/725 | .19/.085 | 4130/Steel | 2.8/71 | .69/18 | .25/6 | No lift tab on front, optional hole at top front if required |

| FDC1575C-2 | 600/273 | .19/.086 | Stainless/Steel | 3.0/76 | .87/22 | .19/5 | With FD1584C Release fitting (Stainless) |

| FDC1575M2-2 | 2000/907 | .18/.081 | 4130/Steel | 2.8/71 | 1.0/258 | .25/6 | Locking type-push tab on front to lock, pull to open |

| FDC1575M14 | 2000/907 | .15/.068 | 4130/Steel | 2.7/69 | .69/18 | .25/6 | No lift tab on front, optional hole at top front if required |

| FDC1575M38 | 2000/907 | .15/.068 | 4130/Steel | 2.6/66 | .69/18 | .25/6 | No lift tab on front, rigid non-pivoting frame |

| FDC1720C-2 | 600/272 | .15/.068 | Stainless/Steel | 3.0/76 | .87/22 | .19/5 | |

| FDC1720-2 | 1000/453 | .16/.072 | 4130/Steel | 3.0/761 | .87/22 | .19/5 | |

| FDC2525-2 | 2000/907 | .19/.086 | 4130/Steel | 3.0/76 | 1.06/27 | .38/10 | |

| FDC5525-2 | 2500/1134 | .47/.213 | 4130/Steel | 4.0/102 | 1.5/38 | .38/10 | Engages ring with minimum I.D. of1.75in [44 mm] Use NW170 web |

Adjustable Ty-Clips

- For use with any 1″ Web

- Strength ratings are for buckles using NW200 Web

- If used with web NW196 assembly strength rating is a max. 1800 lbs. [816 kg.] before web failure

| PART NO. | Strength LBS/Kg | Weight LBS/Kg | Material | A IN./MM | B IN./MM | C IN./MM | Notes |

|---|---|---|---|---|---|---|---|

| FDC1575AM1 | 2000/907 | .15/.068 | 4130/Steel | 2.8/71 | .87/22 | .25/6 | |

| FDK1575AM1 | 2000/907 | .16/.072 | 4130/Steel | 2.8/71 | .87/22 | .25/6 | Includes FD1584 Release Fitting |

| FDC1575AN-2 | 1500/680 | .08/.036 | Alum/Steel | 2.8/71 | .87/22 | .25/6 | Steel cover, alum frame |

| FDC1575M3-2 | 2000/907 | .16/.072 | 4130/Steel | 2.5/63 | .87/22 | .25/6 | Locking type-push tab on front tolock, pull to open |

| FDC1720A-2 | 1250/566 | .06/.026 | Alum/Steel | 2.8/71 | .87/22 | .19/5 | Steel cover, alum frame |

| FDC4483 | 5000/2268 | .50/.226 | 4130/Steel | 3.8/97 | 1.2/30 | .38/10 |

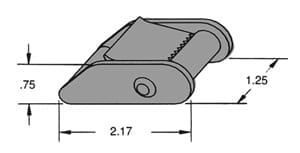

Non-Adjustable Ty-Clips

- For use with any 1″ Web

- Strength ratings are for buckles using NW200 Web

- If used with web NW196 assembly strength rating is a max. 2000 lbs. [907 kg.] before web failure

| PART NO. | Strength LBS/Kg | Weight LBS/Kg | Material | Notes |

|---|---|---|---|---|

| 9006-225 | 660/300 | .13/.059 | Zinc | Olive drab finish |

| 9008-434 | 660/300 | .13/.059 | Zinc | Type I finish |

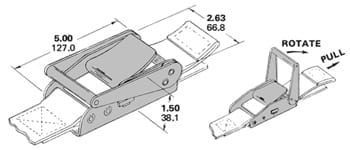

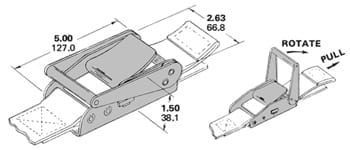

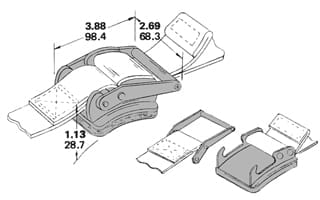

Cam Buckle

- Push to release

- One piece die cast frame

| PART NO. | Strength LBS/Kg | Weight LBS/Kg | Material | Notes |

|---|---|---|---|---|

| FDA8071 | 1000/453 | .18/.08 | Steel | For use with any 1″ web up to .063 thick |

| FDA8071M | 1000/453 | .22/.10 | Steel | For use with any 1″ web up to .10 thick |

Over Center Buckle

- 1″ take-up on locking

- Spring-loaded Keeper

- FDA8071M incorporates .31″ dia. [7.8 mm] hook at back end

- Releasable under load

| PART NO. | Strength LBS/Kg | Weight LBS/Kg | Material | Notes |

|---|---|---|---|---|

| FDA3606-1 | 2000/906 | .26/.11 | Alum/Steel | Web-NW200 orNW196 (1800 lbs. [816 kg.]) |

Tension Buckle Assembly

- Low silhouette, over center

- 2″ Take-up on locking

- Unlock and lift to release

- Separable

- Releasable under load

| PART NO. | Strength LBS/Kg | Weight LBS/Kg | Material | Notes |

|---|---|---|---|---|

| FDA3320C-1 | 1000/453 | .33/.15 | Alum/Steel | Web-NW200 orNW196 (600 lbs. [272 kg.]) |

Lever Tension Buckle

- Unlimited ratchet take-up

- Lift to release web

- Releasable under load

- Can be used with FD1159-2 on back pin (to make assembly separable)

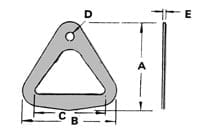

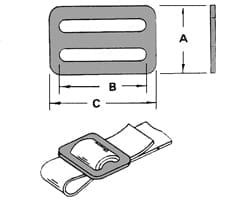

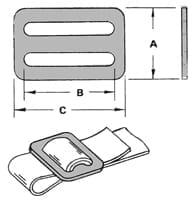

Buckles: 1 1/4″ Web

Adjusters: 1 1/4″ Web

Davis makes two basic types of adjusters for 1 inch web: the friction type, and the spring loaded cam type.

| PART NO. | Strength LBS/Kg | Weight LBS/Kg | Material | A IN./MM | B IN./MM | C IN./MM |

|---|---|---|---|---|---|---|

| FD1932-1 | 2100/951 | .050/.022 | 4130/Steel | 1.44/36.5 | 1.25/31.7 | 1.68/42.7 |

| FD1932-2 | 700/318 | .018/.010 | 2024/Alum | 1.44/36.5 | 1.25/31.7 | 1.68/42.7 |

| FD1589 | 1100/498 | .018/.010 | 2024/Alum | 1.06/26.9 | 1.44/36.6 | 1.88/47.8 |

Bar Slide

- Web – NW227

| PART NO. | Strength LBS/Kg | Weight LBS/Kg | Material | A IN./MM | B IN./MM | C IN./MM |

|---|---|---|---|---|---|---|

| FDA1578M4 | 2100/952 | .12/.05 | 4130/Steel | 2.00/50.8 | .60/15.0 | 1.63/41.3 |

High Strength

- Web – NW227

- Friction Locking

| PART NO. | Strength LBS/Kg | Weight LBS/Kg | Material | A IN./MM | B IN./MM | C IN./MM |

|---|---|---|---|---|---|---|

| FDK1616 | 600/272 | .065/.03 | 4130/Steel | 2.81/71.4 | .75/19.0 | 1.50/38.0 |

Friction Loc

- No moving parts

- Lift tab to release load

- Web – NW227

| PART NO. | Strength LBS/Kg | Weight LBS/Kg | Material | A IN./MM | B IN./MM | C IN./MM |

|---|---|---|---|---|---|---|

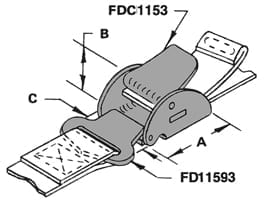

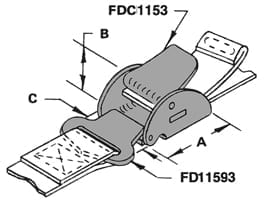

| FDK1153 | 500/227 | .125/.07 | Alum/Steel | 1.65/41.9 | .94/23.0 | 1.66/42.2 |

Cam Type

- Includes FD1159-3 Hook

- FDC1153 Buckle without release hook (700 lbs. [317 kg.])

- FDC1153 Buckle may be used with FDA1682-4

- Web – NW227

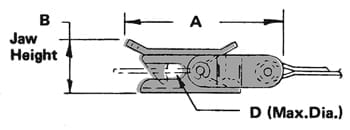

Ty-Clips: 1 1/4″ Web

Ty-Clips are our most extensively used buckles for cargo nets and general purpose tiedowns.

| PART NO. | Strength LBS/Kg | Weight LBS/Kg | Material | A IN./MM | B IN./MM | C IN./MM | Notes |

|---|---|---|---|---|---|---|---|

| FDC1575M2-3 | 2000/907 | .19/.086 | 4130/Steel | 2.8/71 | 1.0/25 | .25/6 | Locking type-push tab on front to lock, pull to open |

| FDK1575M2-3 | 2000/907 | .22/.10 | 4130/Steel | 2.8/71 | 1.0/25 | .25/6 | Locking type-same as above but with FD1584 Rel.ftg. incl. |

| FDC1720-3 | 1250/567 | .17/.07 | Alum/Steel | 3.0/76 | .87/22 | .19/5 | |

| FDC2525-3 | 2000/907 | .20/.09 | 4130/Steel | 3.1/79 | 1.1/27 | .38/10 | |

| FDC2525M2-3 | 2000/907 | .22/.10 | 4130/Steel | 2.9/41 | 1.1/27 | .38/10 | Locking type-push tab on front to lock, pull to open |

Adjustable Ty-Clips

- Strength ratings based on tests with NW227 Web

- For use with any type 1-1/4″ [32 mm] Web

| PART NO. | Strength LBS/Kg | Weight LBS/Kg | Material | A IN./MM | B IN./MM | C IN./MM | Notes |

|---|---|---|---|---|---|---|---|

| FDC1575AM1-3 | 2000/907 | .16/.07 | 4130/Steel | 2.8/71 | .87/22 | .25/6 | |

| FDC1575M3-3 | 2000/907 | .17/.08 | 4130/Steel | 2.5/63 | .87/22 | .25/6 | Locking type-push tab on front to lock, pull to open |

| FDC1720A-3 | 1250/567 | .06/.03 | Alum/Steel | 2.8/71 | .87/22 | .19/5 | Steel cover, alum frame |

| FDC2525M3-3 | 2000/907 | .19/.09 | Alum/Steel | 2.9/74 | 1.1/28 | .38/10 | Locking type-push tab on front to lock, pull to open |

Non-Adjustable Ty-Clips

- Strength ratings based on tests with NW227 Web

- For use with any type 1-1/4″ [32 mm] Web

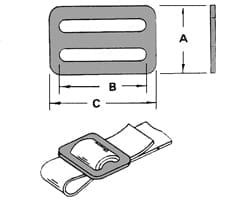

Buckles: 1 1/2″ Web

Adjusters: 1 1/2″ Web

Davis makes two basic types of adjusters for 1 inch web: the friction type, and the spring loaded cam type.

| PART NO. | Strength LBS/Kg | Weight LBS/Kg | Material | A IN./MM | B IN./MM | C IN./MM |

|---|---|---|---|---|---|---|

| FD1589 | 700/317 | .02/.01 | 2024/Alum | 1.06/26.9 | 1.44/36.6 | 1.88/47.7 |

Bar Slide

- Web – NW183

| PART NO. | Strength LBS/Kg | Weight LBS/Kg | Material | A IN./MM | B IN./MM | C IN./MM |

|---|---|---|---|---|---|---|

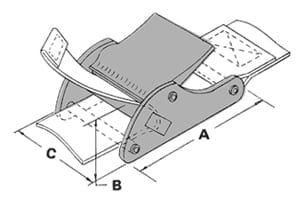

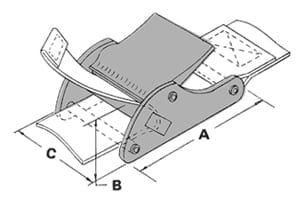

| FDA1481 | 500/227 | .017/.08 | 4130/Steel | 2.4/60.9 | .59/15.0 | 2.2/55.8 |

All Steel

- Web can be sewn directly to FDA1480, eliminating FD1498

- Rotate FD1498 by 90° for release from buckle

- Web – NW183

| PART NO. | Strength LBS/Kg | Weight LBS/Kg | Material | A IN./MM | B IN./MM | C IN./MM |

|---|---|---|---|---|---|---|

| FDC4511F-15 | 2100/952 | .28/.13 | Alum/Steel | 3.0/76.1 | 1.47/37.3 | 1.9/48.2 |

NAS1211F15

- Can be used with Release Hook FDA1682-4

- Cam Type Adjuster

- Web – NW265

| PART NO. | Strength LBS/Kg | Weight LBS/Kg | Material | A IN./MM | B IN./MM | C IN./MM |

|---|---|---|---|---|---|---|

| FDC4511G-15 | 2100/952 | .43/.20 | Steel/Alum | 5.05/128.3 | 2.0/50.7 | 1.9/48.2 |

Adjuster with Hook

- Per NAS1211G15 except for overall length

- Web – NW265

- Cam Type Adjuster similar to FDC4511F-15 with an attachment hook

| PART NO. | Strength LBS/Kg | Weight LBS/Kg | Material | A IN./MM | B IN./MM | C IN./MM | Notes |

|---|---|---|---|---|---|---|---|

| FDC1575M2-4 | 2000/907 | .19/.09 | 4130/Steel | 3.1/79 | 1.0/25 | 1.25/6.3 | Locking type-push tab on front to lock, pull to open |

| FDA1720-4 | 2000/907 | .19/.09 | 4130/Steel | 3.3/83.8 | .94/24 | .25/6.3 |

Adjustable Ty-Clips

- For use with any type 1-1/2″ [39 mm] Web

- Strength rating based on NW265 Web

| PART NO. | Strength LBS/Kg | Weight LBS/Kg | Material | A IN./MM | B IN./MM | C IN./MM | Notes |

|---|---|---|---|---|---|---|---|

| FDC1575AM1 | 2000/907 | .15/.07 | 4130/Steel | 2.6/66 | 1.2/30 | .25/6.3 | |

| FDC1575M3-4 | 2000/907 | .16/.07 | 4130/Steel | 2.5/64 | 1.2/30 | .25/6.3 | Locking type-push tab on front to lock, push to open |

Non-Adjustable Ty-Clips

- For use with any type 1-1/2″ [39 mm] Web

- Strength rating based on NW265 Web

Buckles: 1 3/4″ Web

Adjusters: 1 3/4″ Web

Davis makes two basic types of adjusters for 1 inch web: the friction type, and the spring loaded cam type.

| PART NO. | Strength LBS/Kg | Weight LBS/Kg | Material | A IN./MM | B IN./MM | C IN./MM |

|---|---|---|---|---|---|---|

| FD3543M1 | 2000/907 | .08/.04 | .125/Steel | 1.50/38 | 1.75/44 | 2.25/57 |

| FD8342-11 | 9000/4083 | .33/.15 | .250/Steel | 2.30/58 | 1.81/46 | 2.81/71 |

Bar Slide

- Web – NW160, DW1177, NW188, NW256

| PART NO. | Strength LBS/Kg | Weight LBS/Kg | Material | A IN./MM | B IN./MM | C IN./MM |

|---|---|---|---|---|---|---|

| FDA5650M | 3250/1474 | .39/.17 | 4130/Steel | 2.4/61 | .87/22 | 2.2/56 |

HBU-5B/A

- Pull Tab Release

- Cam Type Adjuster

| PART NO. | Strength LBS/Kg | Weight LBS/Kg | Material | A IN./MM | B IN./MM | C IN./MM |

|---|---|---|---|---|---|---|

| FDC5411F-17 | 2100/907 | .30/.14 | Alum/Steel | 3.00/76 | 1.47/37 | 2.03/52 |

| FDC4511F-17M2 | 2600/1180 | .40/.18 | Alum/Steel | 3.0/76 | 1.47/37 | 2.03/52 |

NAS1211F17

- Web-NW160

| PART NO. | Strength LBS/Kg | Weight LBS/Kg | Material | A IN./MM | B IN./MM | C IN./MM |

|---|---|---|---|---|---|---|

| FDC4511G-17 | 2100/952 | .45/.20 | Alum/Steel | 5.50/140 | 2.00/51 | 2.03/52 |

Adjuster with Hook

- Web-NW160

- Cam Type Adjuster similar to FDC4511-17 with an additional hook

| PART NO. | Strength LBS/Kg | Weight LBS/Kg | Material | Notes |

|---|---|---|---|---|

| FDC2525-8 | 5000/2270 | .496/.224 | 4130/Steel | Non-adjustable Engages Stock DIA .375 [9.5 mm] |

| FDC1575-5 | 2000/907 | .28/.13 | Steel/Alum | Engages Stock DIA .25 [6.3 mm] |

| FDC2525-5 | 2000/907 | .30/.14 | Steel/Alum | Engages Stock DIA .375 [9.5 mm] |

Ty-Clips

- Adjustable with lift or press to release

- For use with any 1-3/4″ [44 mm] Web

- Engages ring minimum I.D. of 1″ [25 mm]

| PART NO. | Strength LBS/Kg | Weight LBS/Kg | Material | Notes |

|---|---|---|---|---|

| FDK1448-1 | 800/363 | .22/.10 | Aluminum | |

| FDK1448-2 | 2000/907 | .34/.15 | 4130/Steel | |

| FDK1448M1 | 800/363 | .25/.11 | Aluminum | Locking type-push tab on front cover to lock, pull to unlock |

| FDK1448M2 | 2000/907 | .38/.17 | 4130/Steel | Locking type-push tab on front cover to lock, pull to unlock |

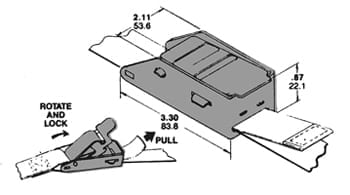

Tie Down Buckle

- Lift to release

- Locking and Non Locking types

- Releasable under load

- Web NW159 or DW167

| PART NO. | Strength LBS/Kg | Weight LBS/Kg | Material |

|---|---|---|---|

| FDA3606 | 2000/907 | .38/.17 | Alum/Steel |

Roll Tight Ty-Down

- 1-1/4″ Pretention take-up

- Web – any type 1 3/4

- Our simplest most adaptable over center device

| PART NO. | Strength LBS/Kg | Weight LBS/Kg | Material |

|---|---|---|---|

| FDA3320-4 | 1250/567 | .87/.39 | 2024/Alum |

Lever Tension Buckle

- Unlimited take-up

- Press to release load

- Releasable under load

- Web – NW211, NW188 (750 lbs. [340 kg.]), NW160 (900 lbs. [408 kg.])

- Can be used with Release Hook on back pin (to make buckle separable)

| PART NO. | Strength LBS/Kg | Weight LBS/Kg | Material |

|---|---|---|---|

| FDA3866M15 | 6600/3000 | 1.65/.75 | Steel |

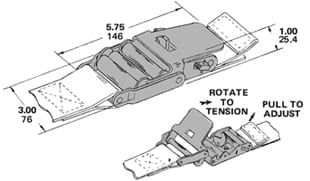

Ratchet Gear

- Type CGU-1/B Ratchet Buckle

- Web NW327

| PART NO. | Strength LBS/Kg | Weight LBS/Kg | Material |

|---|---|---|---|

| FDK8982 | 4000/1814 | .77/.35 | Steel |

Tamper Evident Buckle

- Suitable for securing cargo and containers

- Separable assemblies may be linked with security seal

- Web cannot be worked loose without breaking security seal

| PART NO. | Strength LBS/Kg | Weight LBS/Kg | Material |

|---|---|---|---|

| FDC3435 | 5500/2494 | 1.39/.63 | 4130/Steel |

Tension Buckle Assembly

- Web adjustment

- Self locking, separable

- Web – DW177

- Designed mainly for Cylinder Restraint

- Heavy duty (Built to withstand being run over by vehicles)

| PART NO. | Strength LBS/Kg | Weight LBS/Kg | Material |

|---|---|---|---|

| FDA2533M1 | 7500/3401 | 2.2/1.0 | 4130/Steel |

Cylinder Restraint

- Separable, over center device

- Self locking

- Web adjustment

- Buckle base curved at 15″ [38 cm] radius

- Web – DW177

- Rubber pad can be molded to conform to greater or lesser diameter cylinders

| PART NO. | Strength LBS/Kg | Weight LBS/Kg | Material |

|---|---|---|---|

| FDA2536 | 5000/2268 | .81/.37 | 4130/Steel |

Missile Ty-Down Buckle

- Separable, over center device

- Web adjustment

- Available with Lock per FDA2536M

- Web – NW211, NW159 (2500 lbs. [1130 kg.])

- Rubber pad on bottom made to conform to a 7″ [18 cm] missile radius

Buckles: 2″ Web

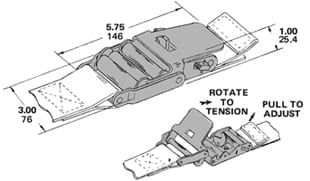

Adjusters: 2″ Web

Davis makes two basic types of adjusters for 1 inch web: the friction type, and the spring loaded cam type.

Features of Friction Adjusters

- High strength to weight/size ratio

- Few parts (No springs)

Features of Cam Adjusters

- Releasable under high loads

- High preloading capability

- Not prone to slippage when slack occurs in assembly

| PART NO. | Strength LBS/Kg | Weight LBS/Kg | Material | A IN./MM | B IN./MM | C IN./MM |

|---|---|---|---|---|---|---|

| FD1110-1 | 3000/1361 | .09/.041 | 4130/Steel | 1.60/40.6 | 2.05/52.1 | 2.51/63.7 |

| FD1595-1 | 2100/952 | .08/.04 | 4130/Steel | 1.27/32.2 | 2.06/52.3 | 2.51/63.7 |

Bar Slide

- FD1110 Series for use with Web NW280

- FD1595 Series for use with Web NW161

- FD1110-2 (Alum) strength 1200 lbs.

- FD1595-2 (Alum) strength 1100 lbs.

- FD1595C (CRES) strength 750 lbs.

| PART NO. | Strength LBS/Kg | Weight LBS/Kg | Material | A IN./MM | B IN./MM | C IN./MM |

|---|---|---|---|---|---|---|

| FDA7271 | 2500/1133 | .11/.05 | Steel/Alum | 1.8/45.7 | .68/17.3 | 2.3/58.4 |

Pull Tab Release

- Friction Lock adjustment

- Chrome-plating

- Web – NW161

- Specify length, color of 1″ pull tab if required

| PART NO. | Strength LBS/Kg | Weight LBS/Kg | Material | A IN./MM | B IN./MM | C IN./MM |

|---|---|---|---|---|---|---|

| FDA4937-2 | 3000/1361 | .27/.12 | 4130/Steel | 2.25/57.1 | .84/21.4 | 2.20/55.8 |

All Steel

- Web – NW161

- Chrome-plating

- Available in Stainless Steel per FDA4937C

- Basic FDA4937 Rated at 1500 lbs. strength (without sleeve)

- Can be used with Release Hook FD4671

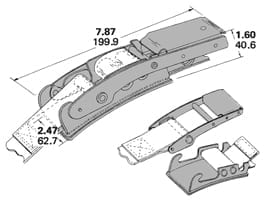

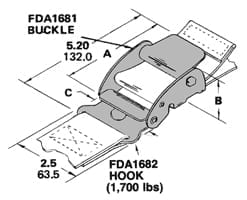

| PART NO. | Strength LBS/Kg | Weight LBS/Kg | Material | A IN./MM | B IN./MM | C IN./MM |

|---|---|---|---|---|---|---|

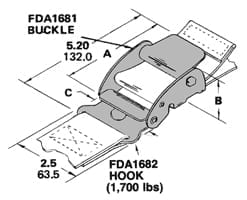

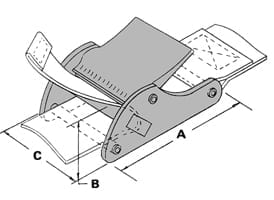

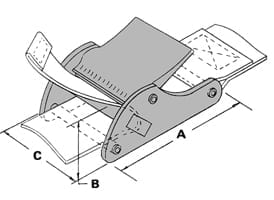

| FDA1681 | 2200/1000 | .38/.17 | 4130/Steel | 3.70/94.0 | 1.06/26.9 | 2.35/59.7 |

Roller Lock Cam

- Lift tab to release load

- Available as shown with FDA1682 Hook (with keeper) or FD4671 (no keeper) or sewn directly to buckle

- Web NW280

| PART NO. | Strength LBS/Kg | Weight LBS/Kg | Material | A IN./MM | B IN./MM | C IN./MM |

|---|---|---|---|---|---|---|

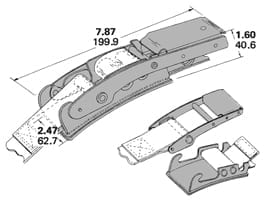

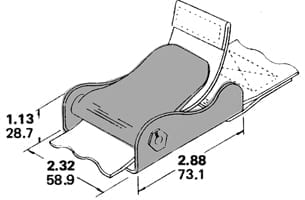

| FDA4511F-20M | 2500/1134 | .33/.15 | Alum/Steel | 3.00/76.1 | 1.45/36.8 | 2.25/57.1 |

NAS1211F20

- Press Cam to release load

- Cam Type adjustment

- Web – NW280 or MIL-W-4088 ty.X (mod.)

- Can be used with Release Hook FD4671 or FDA1682 (with keeper)

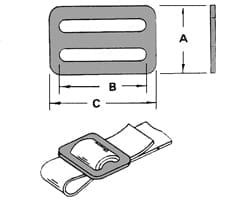

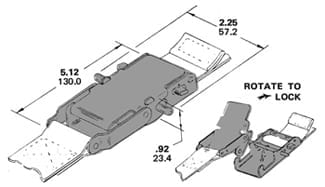

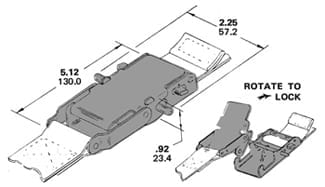

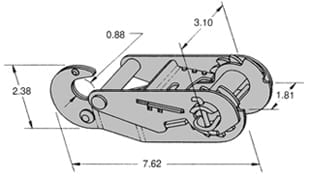

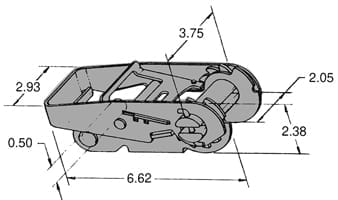

Adjusters – Pickup Type: 2″ Web

These buckles are used extensively in a wide range of cargo tie down applications. Though they represent our most popular stock of items, we have many variations available which are not shown. Also our engineers are always on hand to develop new items to suit your needs.

| PART NO. | Strength LBS/Kg | Weight LBS/Kg | Material |

|---|---|---|---|

| FDA1055M3 | 700/317 | .32/.14 | Alum/Steel |

| FDA2470 | 1400/635 | .35/.16 | Alum/Steel |

Web to Metal Buckle

- Lift cam to release

- Web – NW280

- FDA1055M3 incorporates locking feature

- Used extensively for hospital tie down and personnel restraint

| PART NO. | Strength LBS/Kg | Weight LBS/Kg | Material | A IN./MM | B IN./MM | C IN./MM |

|---|---|---|---|---|---|---|

| FDC1720C-6 | 500/226 | .25/11 | Stainless Steel/Steel | 4.06/103.1 | 1.00/25.4 | .26/6.5 |

| FDC1575M1-6 | 1700/771 | .25/11 | 4130/Steel | 4.06/103.1 | 1.00/25.4 | .26/6.5 |

| FDC2525-6M1 | 1700/771 | .34/.151 | 4130l/Steel | 4.25/107.9 | 1.06/26.9 | .38/9.6 |

Ty-Clip Jaws

- Lift or press tab to release

- Friction lock type adjustment

- Web NW280 or NW161

- Use with D-Ring FD1584 or FD1548C Stainless Steel

| PART NO. | Strength LBS/Kg | Weight LBS/Kg | Material | A IN./MM | B IN./MM | C IN./MM |

|---|---|---|---|---|---|---|

| FDA1123M1 | 1500/680 | .61/.28 | 2024/Alum | 7.5/190.5 | 1.27/32.2 | .91/23.1 |

A1A Tie Down Buckle

- Lift tab to release

- Swivel hook [4130 steel]

- Cam type adjustment

- Available with keepered hook per FDA1123M3

- Per MIL-T-7181

- Web – NW280

| PART NO. | Strength LBS/Kg | Weight LBS/Kg | Material | A IN./MM | B IN./MM | C IN./MM |

|---|---|---|---|---|---|---|

| FDC4511G-20 | 2500/1134 | .49/.22 | Steel/Alum | 5.10/130 | 2.00/50.8 | 1.00/25.4 |

Adjuster with Hook

- Cam Type Adjustment

- 4130 Steel Hook

- Per NAS1211G20 except for overall length

- Web – NW280 [2000 lbs.] or MIL-W-4088 ty.X [Mod]

| PART NO. | Strength LBS/Kg | Weight LBS/Kg | Material |

|---|---|---|---|

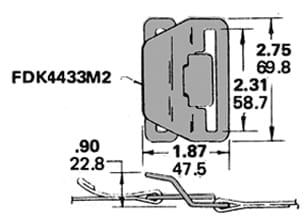

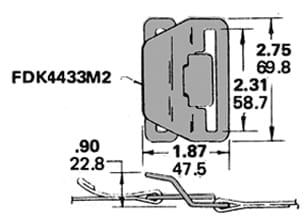

| FDK4433M2 | 200/91 | .07/.03 | 2024/Alum |

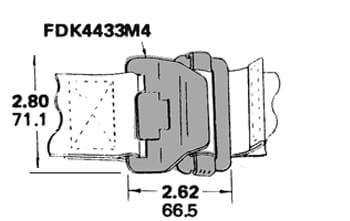

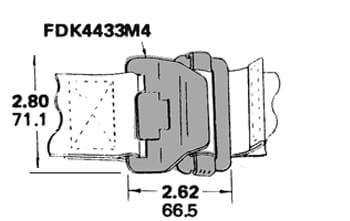

| FDK4433M4 | 450/204 | .10/.05 | 2024/Alum |

Military Personnel Buckle (patented)

- FDK4433M2 Non-adjustable

- FDK4433M4 Adjustable

- Web – NW161, NW280

- Gloss black anodize (other finishes, material available

| PART NO. | Strength LBS/Kg | Weight LBS/Kg | Material |

|---|---|---|---|

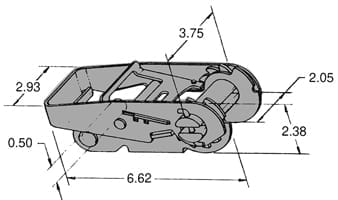

| FDA3866M16 | 10,000/4535 | 2.40/1.10 | Steel |

Ratchet Gear

- Suitable for 2″ [50 mm] and 1-3/4″ [45 mm] web

- Standard for Commercial & Military truck tie down

| PART NO. | Strength LBS/Kg | Weight LBS/Kg | Material |

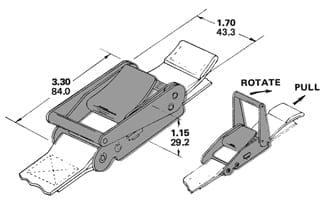

|---|---|---|---|

| FDA5669-3 | 4000/1814 | .81/.36 | 4130/Steel |

Over Center Tensioning Buckle

- Positive locking

- Crushproof steel frame construction

- Smooth underside-does not damage cargo from sharp edges

- Web – NW161 (Higher loads attainable with alternate web types)

| PART NO. | Strength LBS/Kg | Weight LBS/Kg | Material |

|---|---|---|---|

| FDA3320-5 | 2000/907 | .89/.36 | 2024/Alum |

Lever Tension Buckle

- Unlimited take-up

- Press to release web

- Can be used with release hook FDA1682 (Hook with Keeper)

- Web – NW280